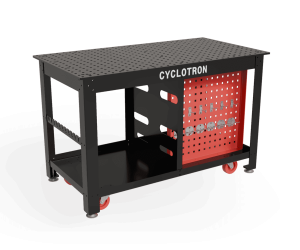

CYCLOTRON 3D WELDING Table

3D Welding table

Modular. Precision Engineered

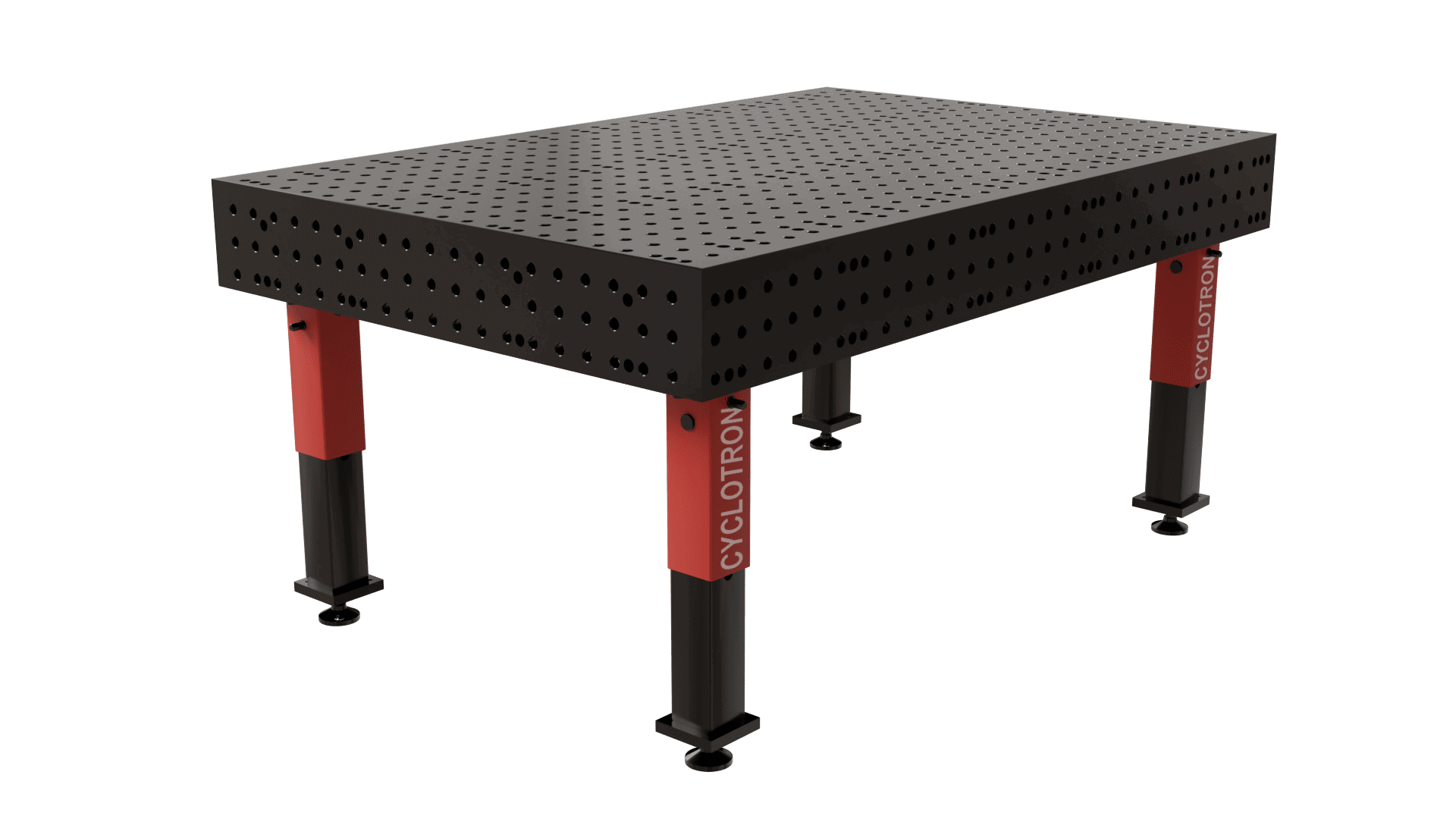

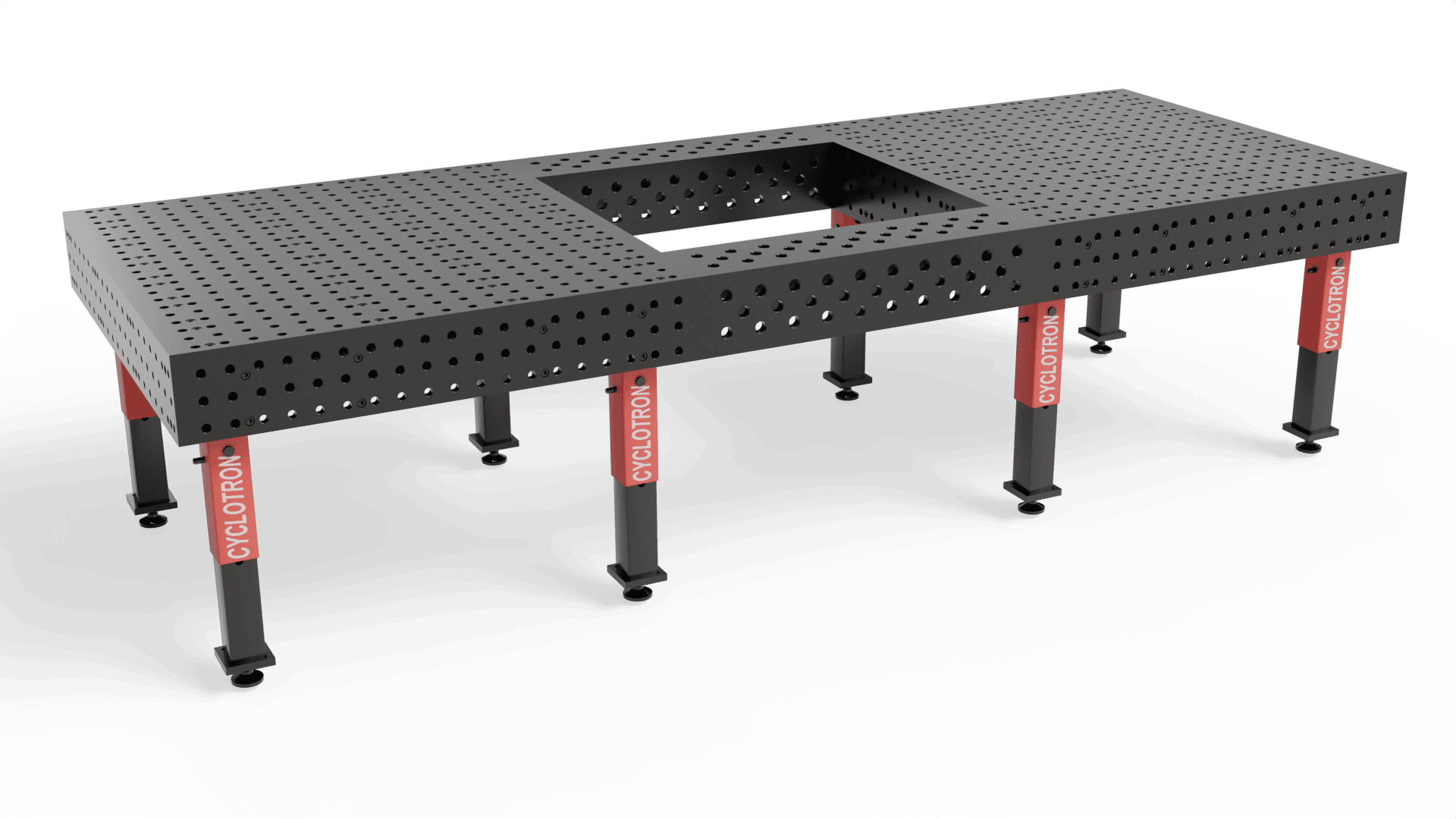

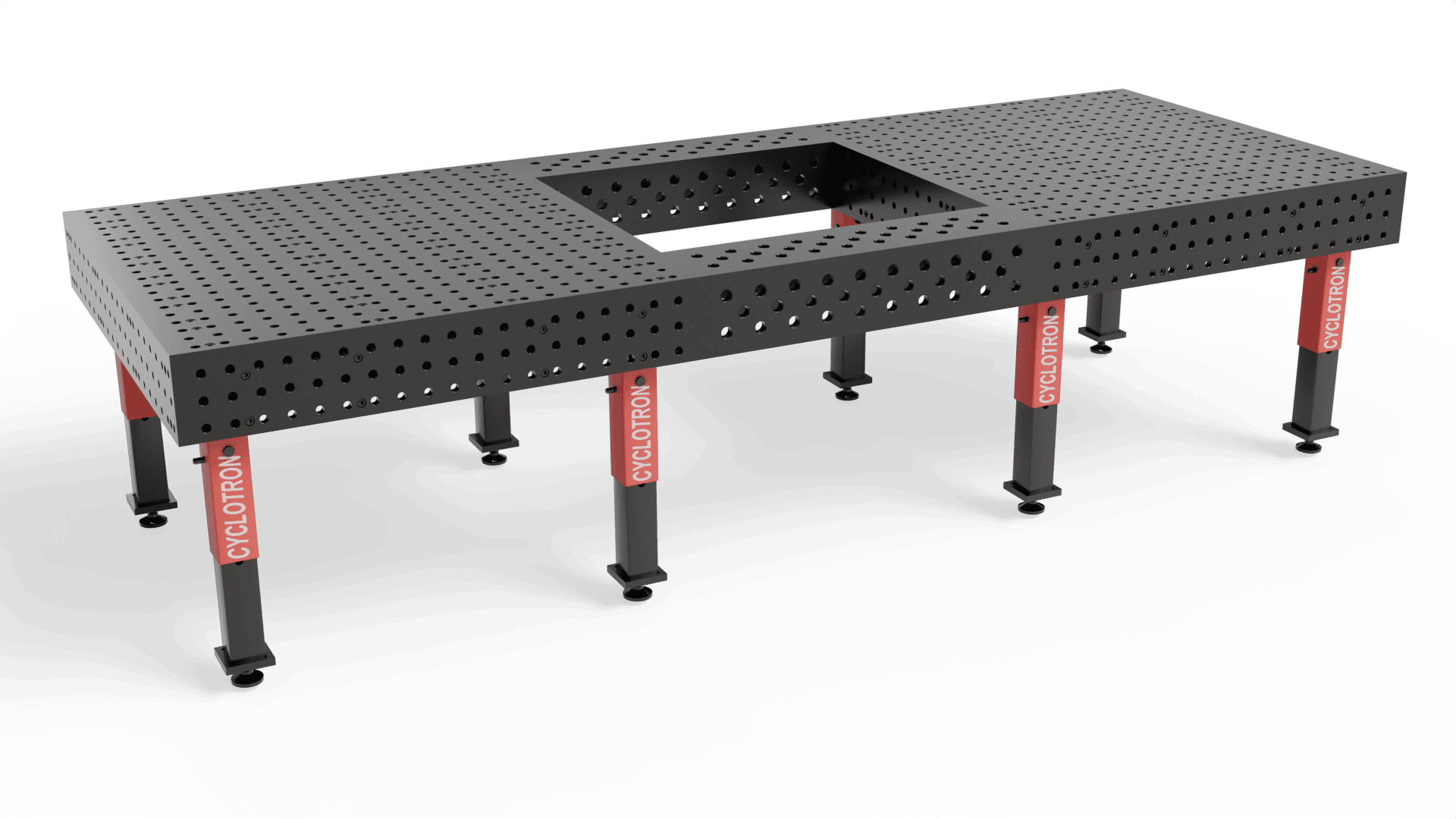

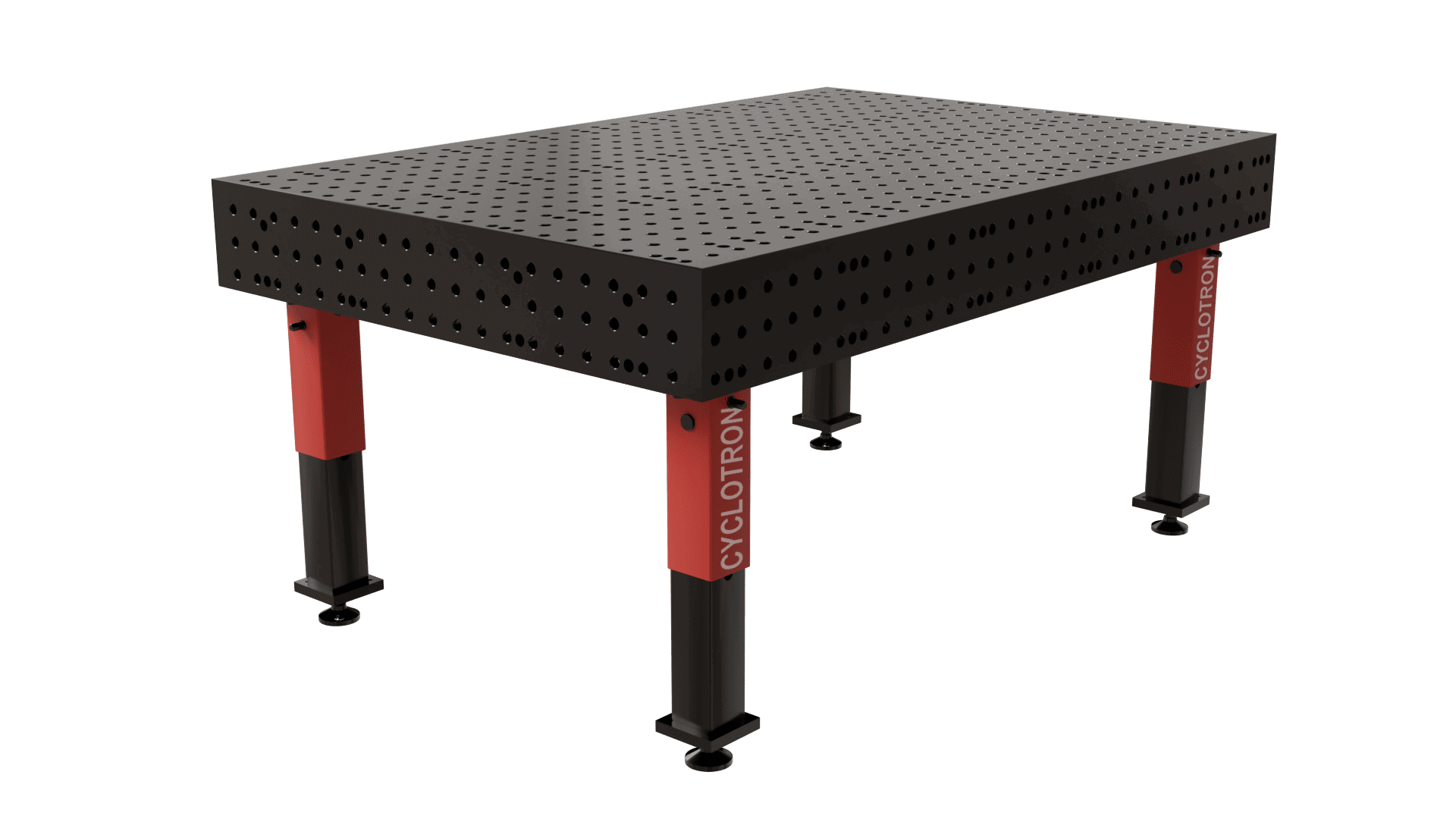

3d Modular welding table has 5 precision machined working surfaces (1 top + 4 side surfaces).

The table is connected and changed arbitrarily according to the shape of the workpiece.

Why Choose the 3D welding tables?

One of the advantages of opting for a 3D welding table is the level of precision it offers. While traditional flat tables may be suitable, for projects intricate welding tasks require precision in every dimension. With a 3D welding table welders have a three workspace that allows them to position their workpieces with accuracy. This not enhances the quality of the welds. Also reduces the need for extensive rework.

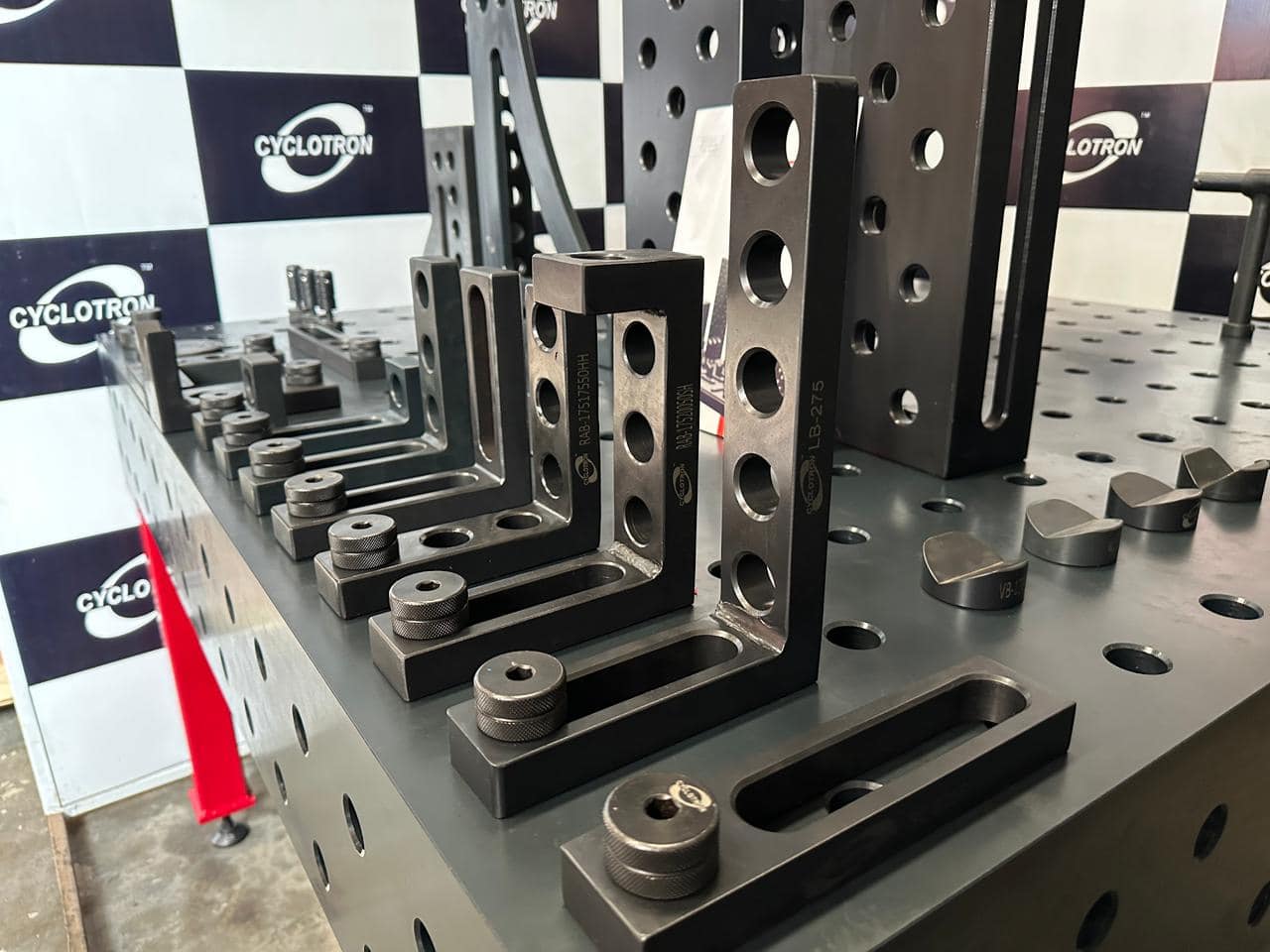

Versatility to Suit Projects

Whether you’re working on a small scale project or tackling scale industrial applications 3D welding tables prove to be highly versatile. The adjustable fixtures and modular design of these tables can accommodate workpieces of sizes and shapes. This adaptability is crucial in todays diverse welding landscape, where professionals often face a range of projects.

Time and Cost Efficiency

In the welding industry time is money and investing in a 3D welding table significantly contributes to time efficiency. The precision provided by these tables minimizes the time spent on adjustments. Ensures that welding tasks are completed efficiently. Additionally by reducing rework requirements businesses can experience cost savings when utilizing 3D welding tables—making them an intelligent investment choice, for optimizing welding processes.

Improved Workflow Ergonomics

Apart from offering accuracy and versatility 3D welding tables also enhance ergonomics.Being able to rotate and tilt the workpieces makes the welding process easier ensuring that professionals can work in an safe manner. This ergonomic benefit not improves productivity. Also contributes to the overall well being of welding operators.

D16-3D Welding table Sizes

| Size | Capacity | Side Plate | Grid |

|---|---|---|---|

| 600x600 | 400 | 150 | 50/100 |

| 600x1050 | 500 | 150 | 50/100 |

| 600x1200 | 600 | 150 | 50/100 |

| 600x1500 | 700 | 150 | 50/100 |

| 600x3000 | 800 | 150 | 50/100 |

| 800x1200 | 600 | 150 | 50/100 |

| 800x1950 | 800 | 150 | 50/100 |

| 1000x1000 | 600 | 150 | 50/100 |

| 1000x1200 | 650 | 150 | 50/100 |

| 1000x1500 | 900 | 150 | 50/100 |

| 1000x1950 | 1200 | 150 | 50/100 |

| 1000x3000 | 1800 | 150 | 50/100 |

| 1200x1200 | 700 | 150 | 50/100 |

| 1200x1500 | 1000 | 150 | 50/100 |

| 1200x1950 | 1500 | 150 | 50/100 |

| 1200x2550 | 2000 | 150 | 50/100 |

| 1200x3000 | 2200 | 150 | 50/100 |

| 1500x1500 | 1200 | 150 | 50/100 |

| 1500x3000 | 2500 | 150 | 50/100 |

| 2000x3000 | 2700 | 150 | 50/100 |

| 2000x4050 | 2900 | 150 | 50/100 |

| 2000x6000 | 3200 | 150 | 50/100 |

| 2500x2550 | 2000 | 150 | 50/100 |

| 2550x5100 | 4000 | 150 | 50/100 |

| 3000x3000 | 4500 | 150 | 50/100 |

| 3000x4050 | 5000 | 150 | 50/100 |

| 3000x6000 | 5300 | 150 | 50/100 |

D28-3D Welding table Sizes

| Size | Capacity (kgs) | Side plate | Grid |

|---|---|---|---|

| 600x600 | 800 | 150 | 50/100 |

| 600x1000 | 1000 | 150 | 50/100 |

| 600x1200 | 1200 | 150 | 50/100 |

| 600x2000 | 1200 | 150 | 50/100 |

| 800x1200 | 960 | 150 | 50/100 |

| 800x1600 | 1440 | 150 | 50/100 |

| 800x2000 | 1600 | 150 | 50/100 |

| 800x3000 | 2000 | 150 | 50/100 |

| 1000x1000 | 1000 | 150 | 50/100 |

| 1000x1600 | 1400 | 150 | 50/100 |

| 1000x2000 | 2000 | 150 | 50/100 |

| 1000x2400 | 2200 | 150 | 50/100 |

| 1000x3000 | 3000 | 150 | 50/100 |

| 1200x1200 | 1440 | 150 | 50/100 |

| 1200x2000 | 2200 | 150 | 50/100 |

| 1200x2400 | 2200 | 150 | 50/100 |

| 1200x3000 | 3000 | 150 | 50/100 |

| 1500x1600 | 1500 | 150 | 50/100 |

| 1500x2000 | 2000 | 150 | 50/100 |

| 1500x2400 | 2200 | 150 | 50/100 |

| 1500x3000 | 3000 | 150 | 50/100 |

| 2000x2000 | 4000 | 150 | 50/100 |

| 2000x3000 | 5000 | 150 | 50/100 |

| 2000x4000 | 6000 | 150 | 50/100 |

| 2000x6000 | 6200 | 150 | 50/100 |

| 2500x5000 | 6500 | 150 | 50/100 |

| 2500x6000 | 6800 | 150 | 50/100 |

| 3000x3000 | 7000 | 150 | 50/100 |

| 3000x5000 | 7500 | 150 | 50/100 |

| 3000x6000 | 8000 | 150 | 50/100 |

Cyclotron 3D Welding table

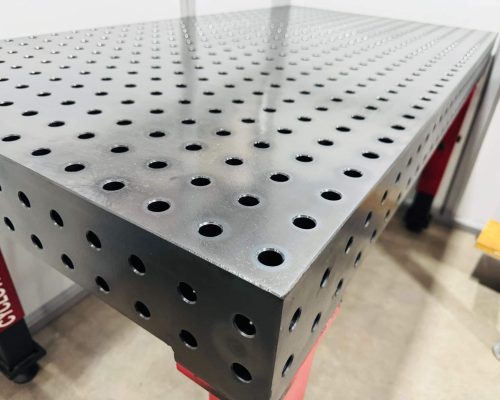

- 3d Modular welding table has a worktop with D16 system bores in a 50 mm x 50 mm grid resulting in greater clamping options as compared to 100mm x 100mm grid .

- Further improving the expansion and clamping options by 3 hole drilling pattern on the side plates with D16 system bores in 50 x 50mm.

- The precision can reach microns for fixing and clamping.

- Cyclotron gives a nitrided surface improving surface properties of metal and corrosion resistance, and increase the fatigue strength.

- Nitriding is a heat-treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface.

- It is mainly used for clamping & locating steel structures and other assembling & fabrications according to our needs.

- It is a widely used welding tool, which helps in modularity, standardization & reusability.

- It replaced traditional dedicated fixtures with its high efficiency /affordability/precision/convenience.

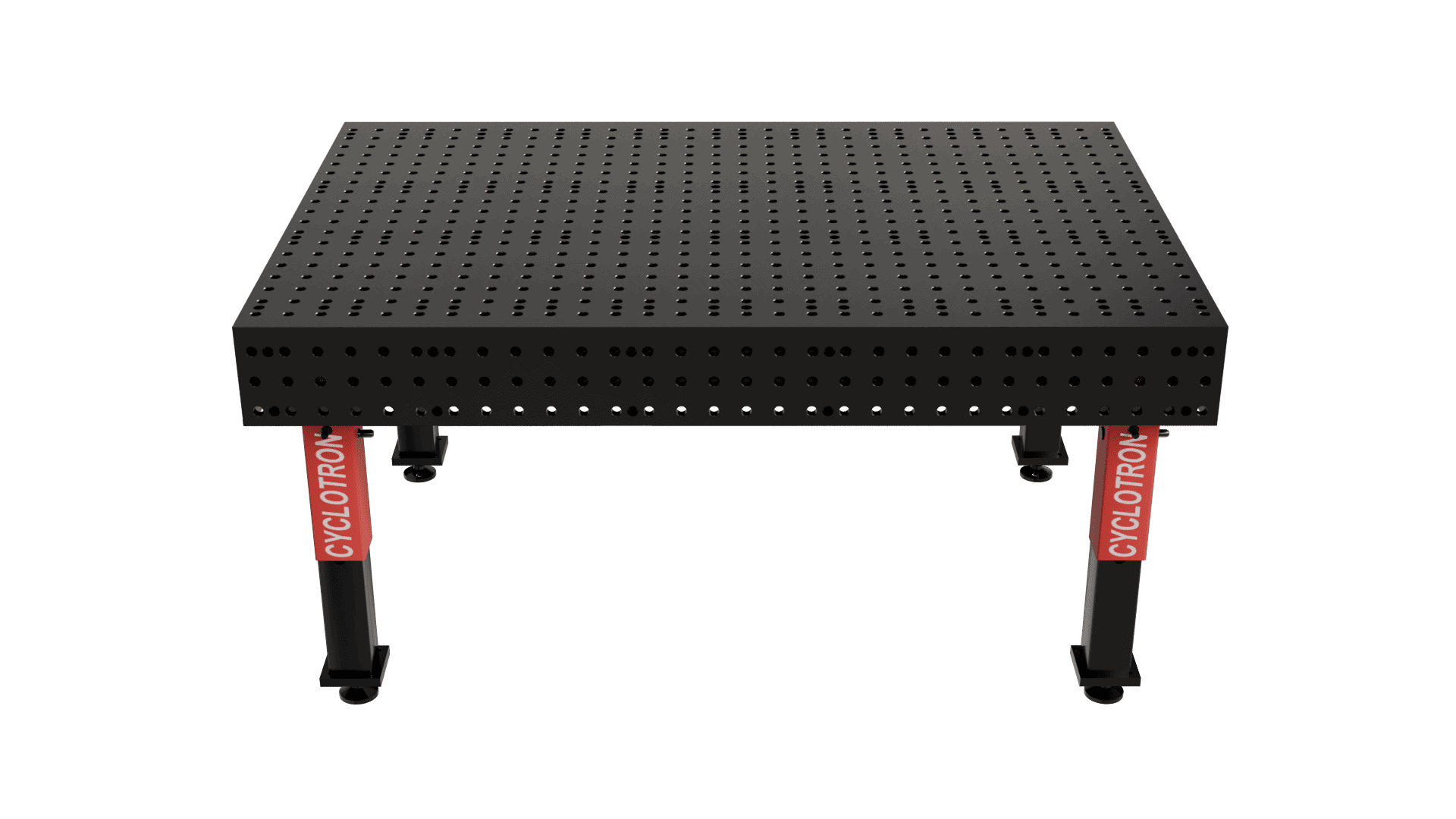

3D Welding table joining with riser blocks

3D welding table

3D welding table