D16-V Block

V Block

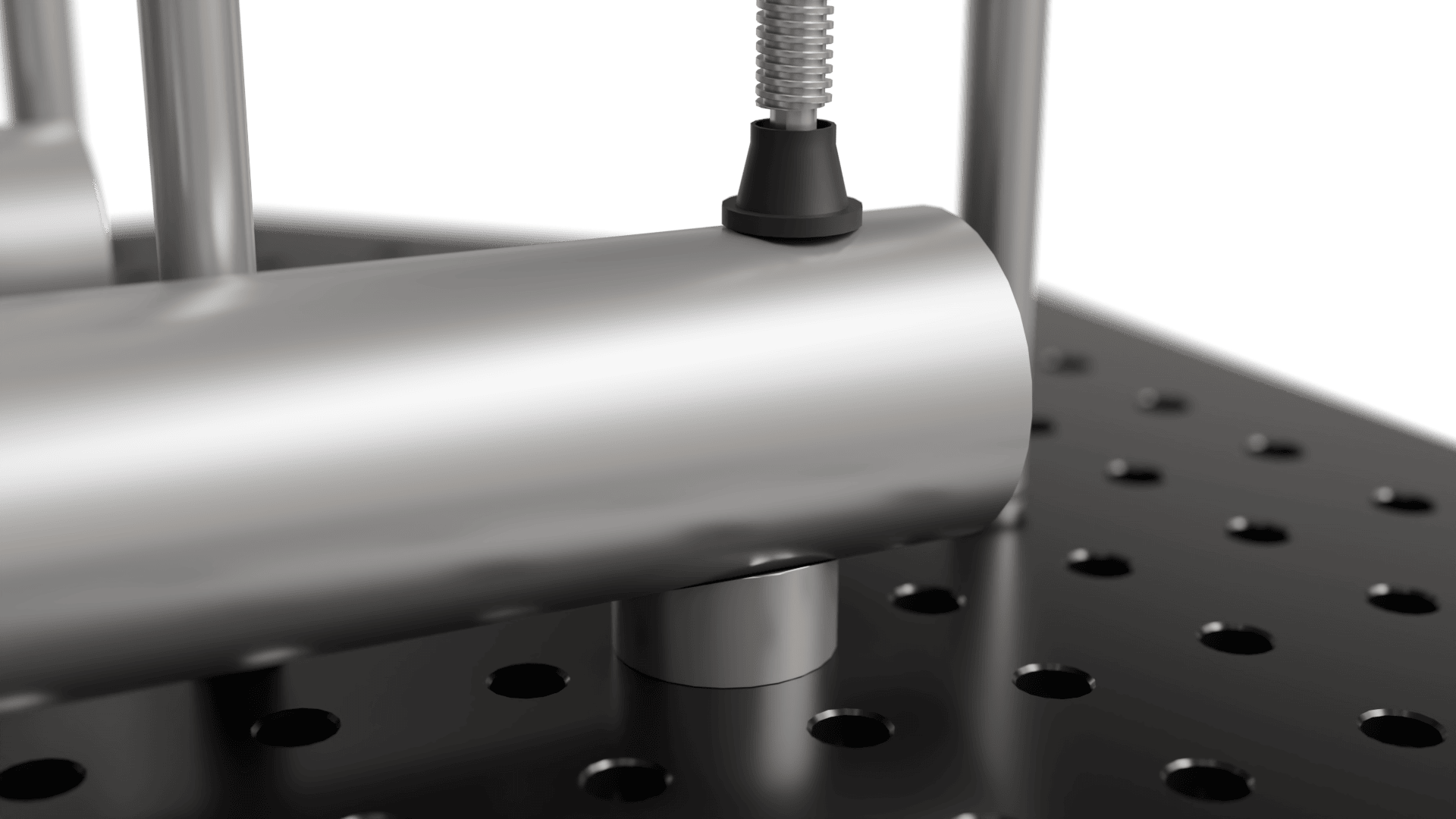

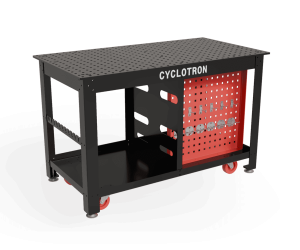

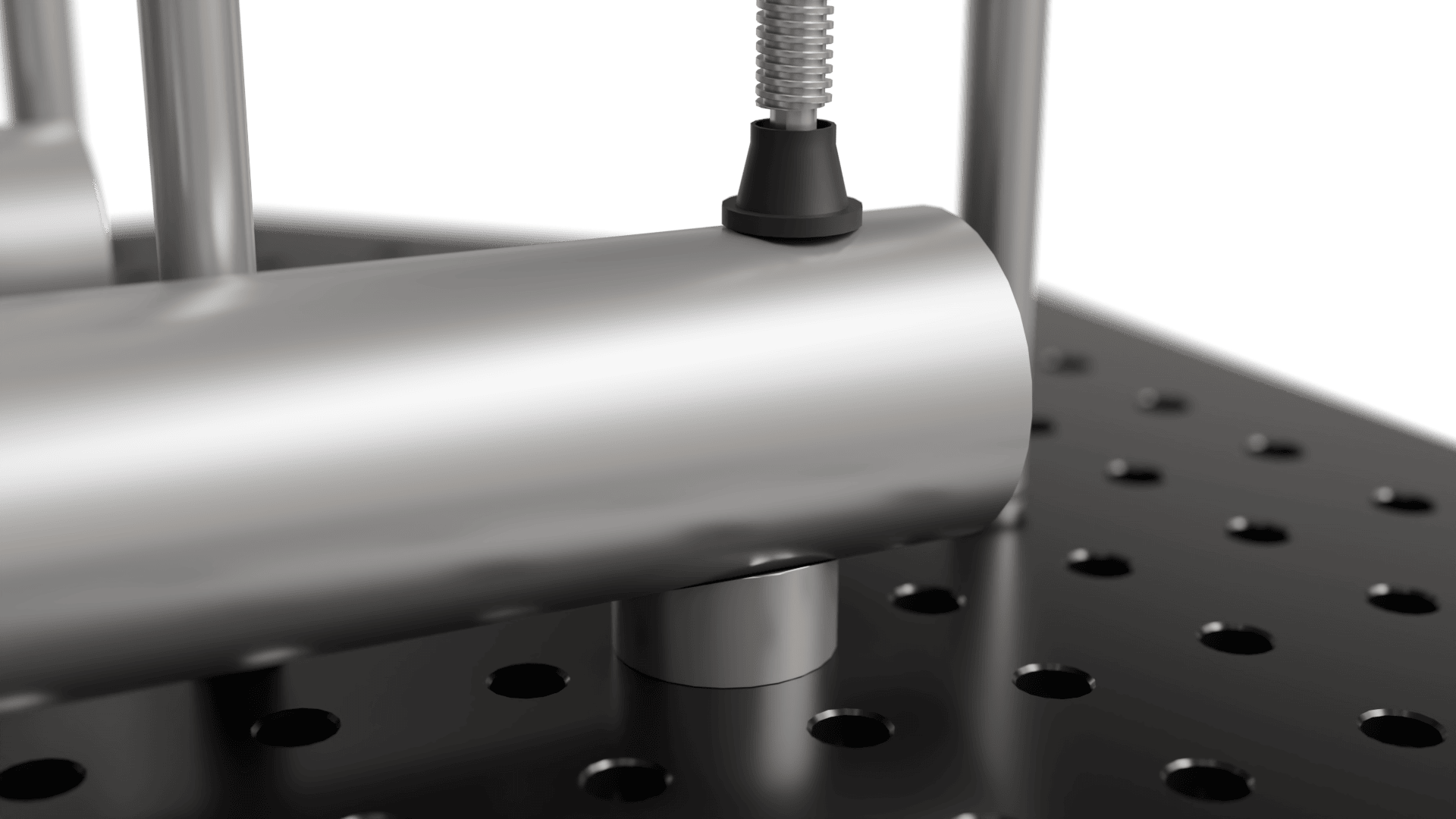

Cyclotron V-Blocks are essential tools for providing stable and precise support for cylindrical, round, or irregularly shaped workpieces. Designed with a V-shaped groove, these blocks securely hold components in place, ensuring accuracy and stability during welding, machining, and assembly operations. Cyclotron V-Blocks are built with high-strength materials to withstand demanding industrial applications while maintaining exceptional performance and durability.

Applications

Elevated Welding and Clamping: Position components at optimal heights for better accessibility.

3D Assembly Configurations: Create multi-dimensional layouts for complex fabrication tasks.

Precision Projects: Achieve accurate positioning for parts that require meticulous alignment.

Heavy-Duty Support: Handle large and heavy workpieces with ease, ensuring stability throughout.

Welding table extensions: These blocks can be used as an extensions for joining 2 or more 3D welding tables.

| Part Name | Part No | Height | Angle |

|---|---|---|---|

| D16 V Block 90 | D16-VB90 | 33 | 90 |

| D16 V Block 120 | D16-VB120 | 28 | 120 |

| D16 V Block 135 | D16-VB135 | 41 | 135 |