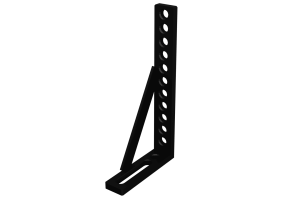

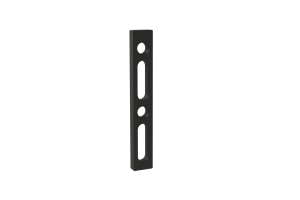

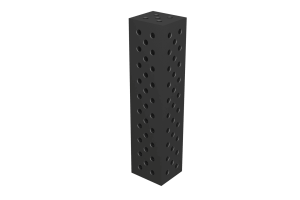

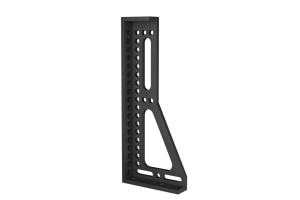

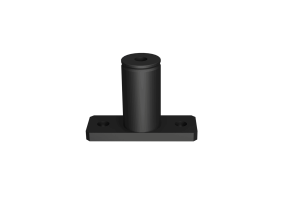

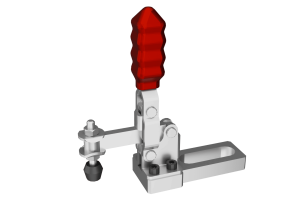

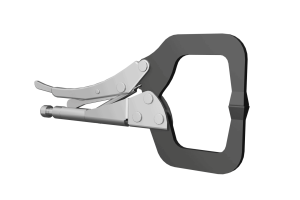

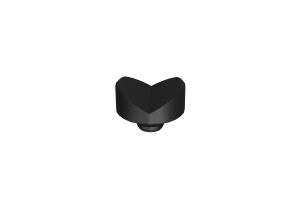

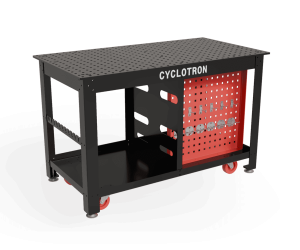

D16-Welding Fixture Clamps

Welding fixture clamps

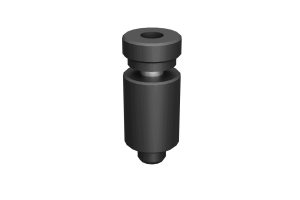

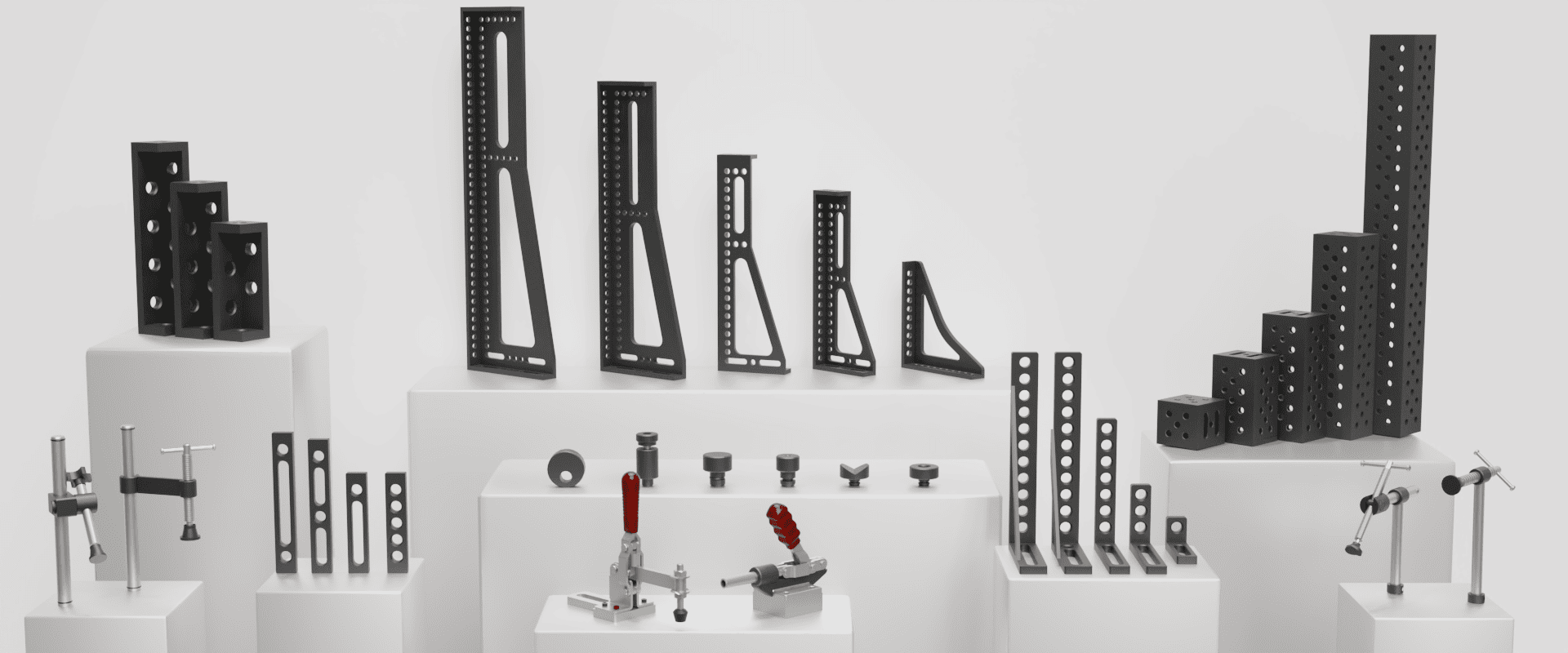

D16 Welding table accessories are devices used to secure workpieces during machining, welding, or assembly operations. They are designed to hold materials firmly in place on a worktable or within a machine tool, preventing movement or vibration that could compromise the precision or quality of the work being performed.

Significance of Fixture clamps

Precision: By securely holding the workpiece in place, fixture clamps ensure that machining or assembly operations can be performed with high precision, which is crucial for maintaining tight tolerances and achieving quality finishes.

Safety: They also enhance safety in the workplace by preventing the workpiece from moving unexpectedly, which could lead to accidents or injuries.

Efficiency: Fixture clamps facilitate quicker setup and changeover times, boosting productivity. They allow for the rapid securing and releasing of workpieces, minimizing downtime between operations.

Versatility: With a wide range of types and sizes available, fixture clamps can accommodate a vast array of workpiece shapes, sizes, and materials, making them indispensable in diverse manufacturing environments.