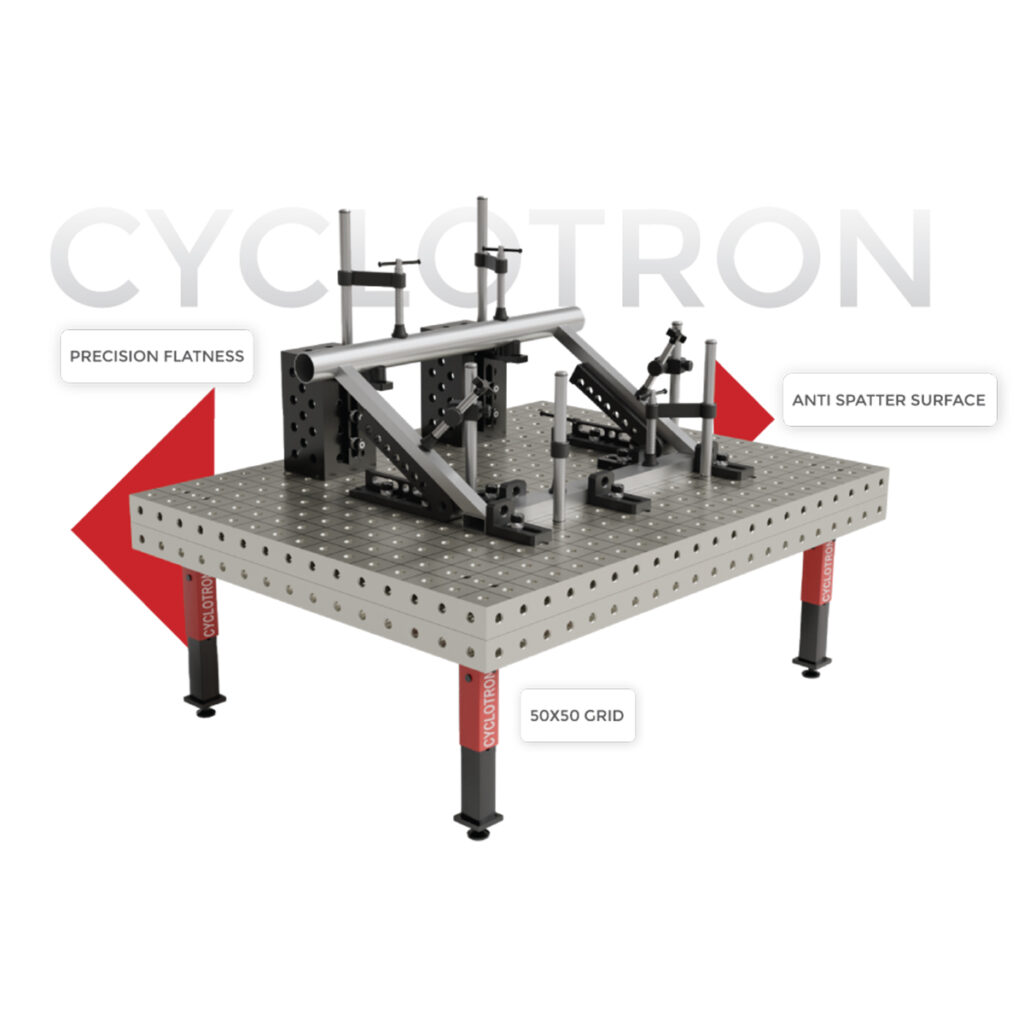

Precision Engineered fixture tables

Cyclotron is India’s largest manufacturer of precision welding tables and clamps. Our table delivers unmatched flatness, strength and modular flexibility-crafted for serious fabricators

3d Modular welding table has 5 precision machined working surfaces (1 top + 4 side surfaces).

The table is connected and changed arbitrarily according to the shape of the workpiece.

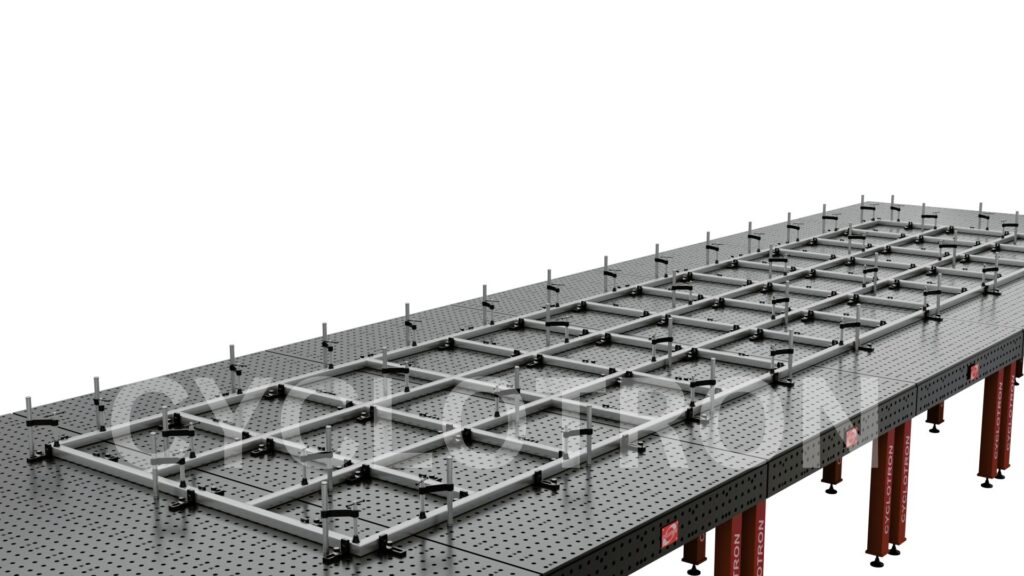

The SEGMENT Series of welding tables offers unparalleled modularity and versatility, enabling users to create custom table configurations tailored to their workspace requirements. Designed for flexibility, strength, and precision.

Made from high-grade cast iron, these welding tables offer exceptional flatness (±0.1 mm tolerance) and superior vibration-dampening properties, making them ideal for high-accuracy applications.

Designed for heavy-duty applications, these tables offer smooth height adjustments, ensuring optimal positioning for precision work. With a sturdy construction and customizable load capacities, they are ideal for workshops requiring flexible and reliable lifting solutions

The ECO-FLEX Series welding tables provide cost-effective tables for light to medium-duty tasks. Built for affordability and functionality, they ensure compatibility with standard fixtures and clamps.

Its octagonal design offers unparalleled flexibility, while the high-grade Cast Iron construction ensures longevity and durability. Ideal for workshops, maintenance tasks, and fabrication projects, the OCT-CAST is your reliable partner for precision work.

Cyclotron’s welding table is suitable for robotic welding and cobot welding processes. The clamps allows the robot to welding accurately holding the product tightly such that it does not move while welding.

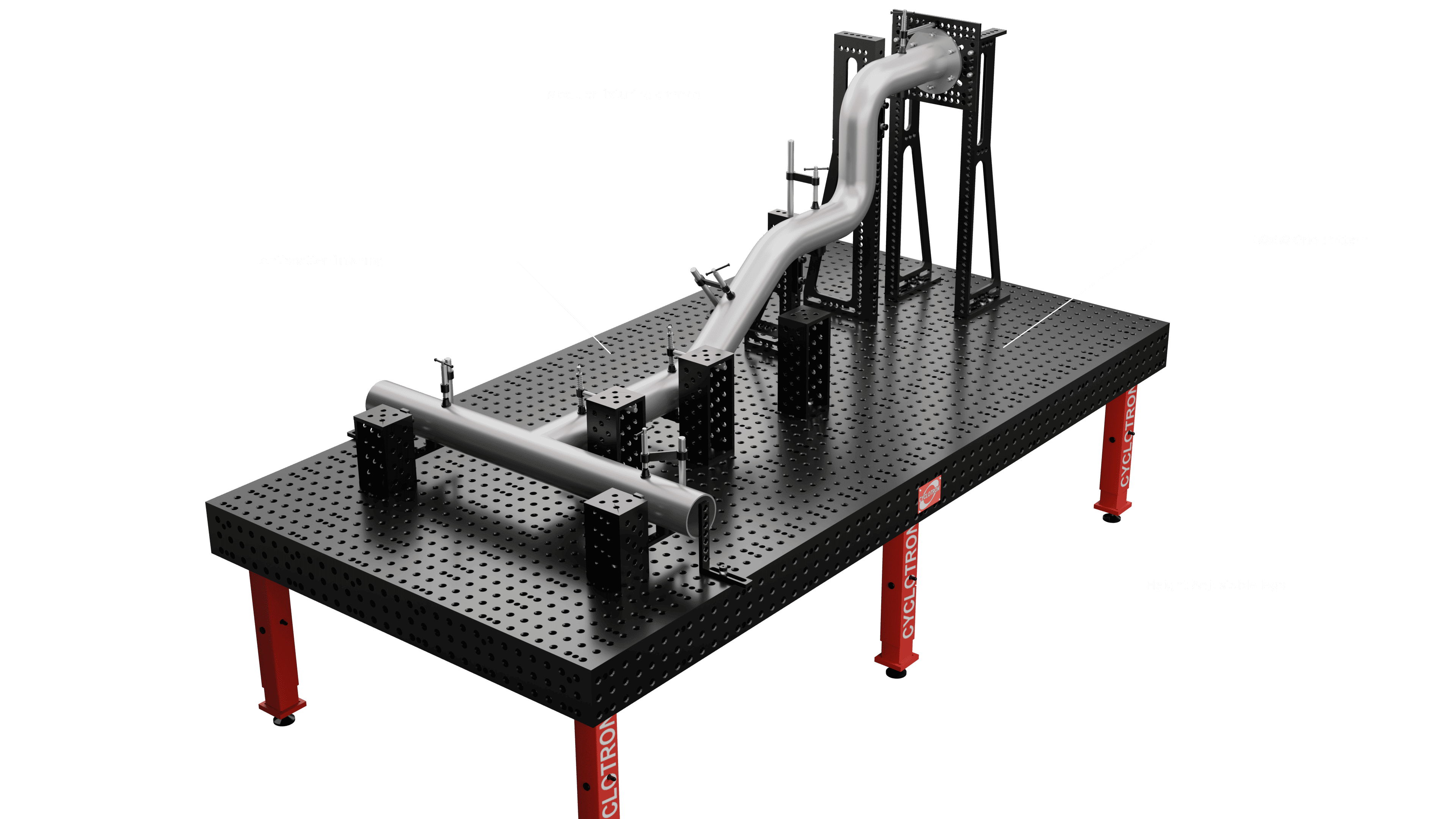

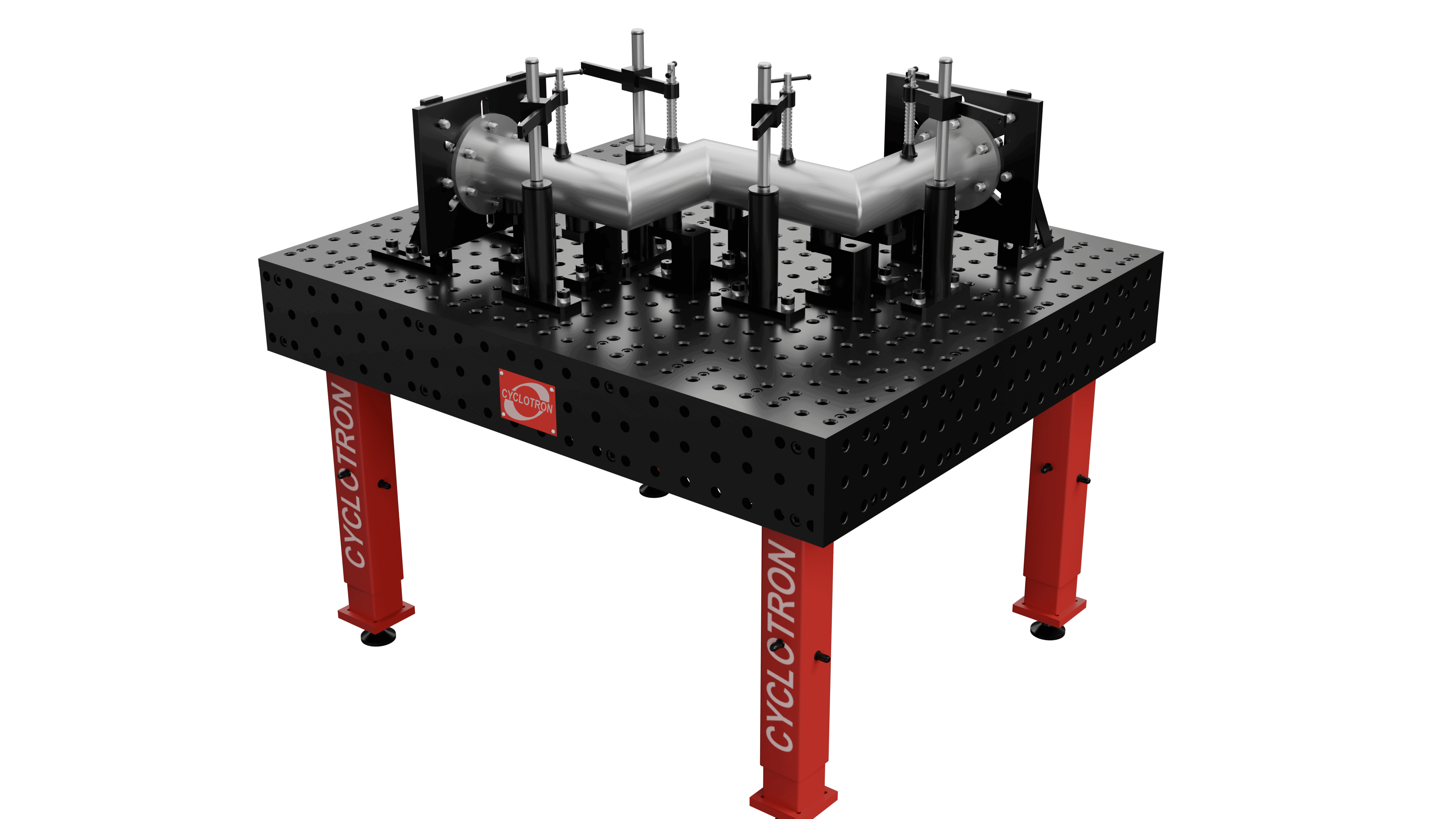

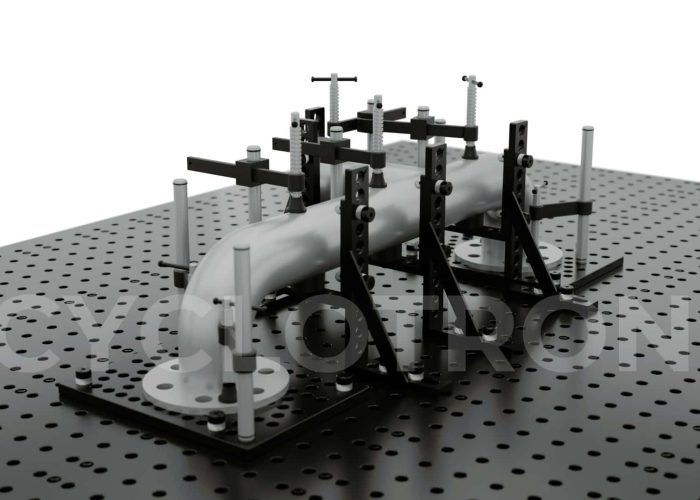

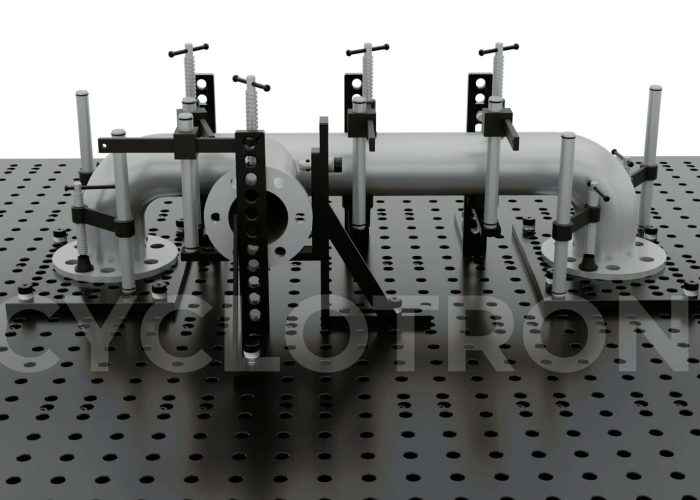

CYCLOTRON modular welding fixture is adaptable according to your needs of fabrication, also repeatability process is quite easy increasing your production quality of pipe welding and quantity thus increase in your business. Our Team of EXPERTS is working for YOU to improve your fabrication process of your pipe welding.

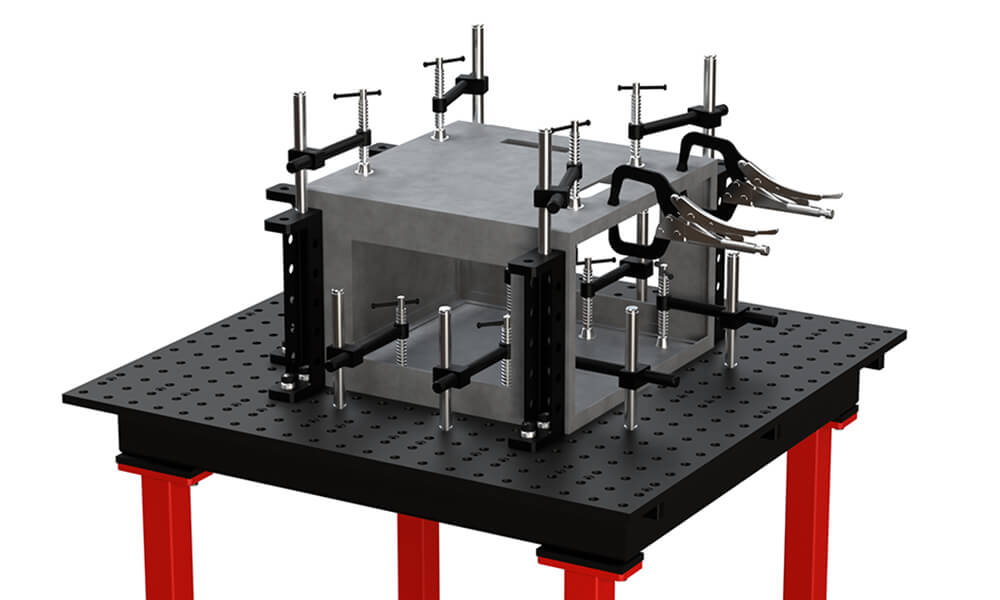

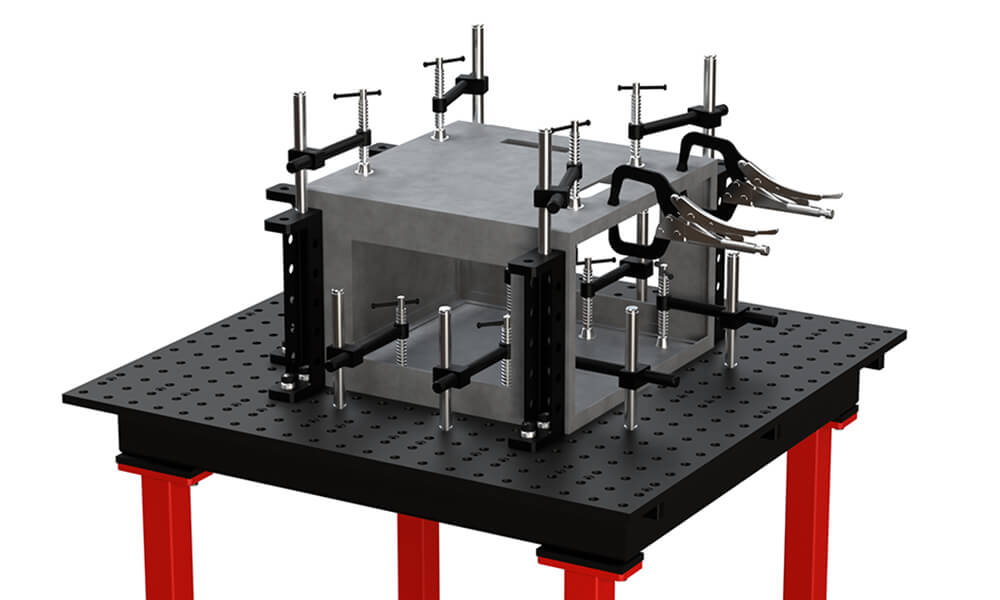

Cyclotron is the leading manufacturer of Enclosure modular welding fixtures. We offer complete set of modular welding tables and clamps which ensures the improvement in your welding quality and overall efficiency of the production.

Increase your production rate-With the table YOU can increase your production rate exponentially by reducing all non-welding activity, and increased manufacturing qualities improvising your business activities.

Increase your Business ROI-Whether affordability, flexibility, and precision are needed for a single production piece or series production, the table gives you a variety of clamping options increasing your business ROI.

Greater Customization– With the most advanced fixture clamping options we provide greater flexibility for welders to do their work efficiently. Clamps like Leg adapters provide an option for increasing your welding table size according to your project needs. Thus making it possible to perform large projects.

AntiSpatter surface– We provide two options of surface table tops. 1-Standard cast-iron surface and 2-Nitrided surface. Both options provide protection from welding spatters. Cleaning the tabletop with abrasive methods is no longer required. Thus offering lifetime accuracy of the tabletop.

Improved Welding Quality

CYCLOTRON is India’s Fastest growing Modular welding table manufacturer.

CYCLOTRON is on the mission of providing the complete range of world’s Finest and Boldest modular welding tables at affordable prices.

The innovation in design, manufacturing and inspection of the product is the true reason for its optimum cost without compromising the quality of the product.

CYCLOTRON modular welding tables is adaptable according to your needs of fabrication, also repeatability process is quite easy increasing your production quality and quantity thus increase in your business.

OUR Team of EXPERTS is working for YOU to improve your fabrication process.

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

Mild steel and cast iron are two common materials used for welding tables. To assist you in selecting the one that best suits your needs, this article deconstructs their salient characteristics.

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.

We offer Value for money products to improve your production quality

Trusted & certified fixture welding table manufacturer at your door step.

Best in class quality products with Quality assessments in each steps we offer

Legs type:

In standard configuration, legs come with two options. With leveling pads or with Castor wheels

WhatsApp us