Benefits of height adjustable welding tables

Height adjustable welding tables

Let’s be honest — most people don’t think about their welding table after they’ve got one. You get a big flat surface, make sure it’s strong enough, and boom — you’re set, right?

But here’s the thing. Once you’ve used a height adjustable welding table, you realize just how much you’ve been compromising all along.

Problem with fix height welding tables

- Welding is not just beads and sparks. Welding is about holding your body in awkward positions for hours, bending, standing on your toes, bending your back for the hundredth time, and getting the welding angle just right. And for what? A fixed-height table that was designed for “average” people doing “average” jobs. But we both know that fabrication doesn't work like that. Parts change. Welders change. Processes change. So why is your table still stuck at the same height?

How adjustable welding table height changes the game

- The beauty of a height adjustable welding table is simple — it adapts to you.

- Are you doing TIG work and need your hands to be steady? Lower the welding table, relax your elbows, and work close to the piece.

Have a large assembly? Lift it up so you’re not bent over like a pretzel and trying to weld underneath. - Want to switch between standing and sitting? Adjust the table and keep going.

It’s not rocket science. It’s just something that makes you think: Why didn’t I figure this out before?

Scissor lift welding tables

-

Some people ask, “Why not just use a manual system? Crank it up or down?” Sure, that works — if you only change height once a week.

But if you’re adjusting multiple times a day (which you will, once you realize how useful it is. That’s why we use a pneumatic system. Press it once and the table raises or lowers smoothly.

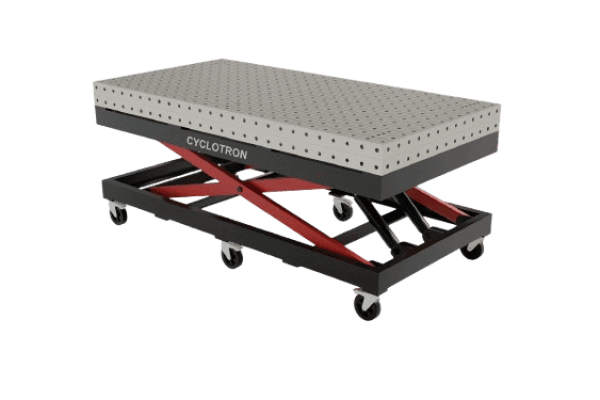

That’s where Cyclotron’s Scissor lift welding tables come into play, where you can automatically adjust the height of your table within a single button click. Simple. Fast. Workshop-approved.

Cyclotron's welding tables

Built for Real Work — Not Just for Show

This isn’t some delicate gadget you have to baby. Our height adjustable tables are made with:

- Heavy-duty MS frame

- Compatible with D16 or D28 tooling (whatever system you’re already using)

- Modular hole system — same clamps, stops, fixtures you already know

- Load capacity strong enough for real-world jobs — not just light assembly

You can move it around the shop if needed (with locking caster options), or fix it in place for daily heavy-duty use.

Basically, it works just like your current welding table — but better.

Cyclotron Height Adjustable Welding Tables

Flexible. Adjustable. Precision-Engineered

The Cyclotron Scissor Lift Welding Tables provide an ergonomic and adjustable work surface, enhancing efficiency and safety in welding and fabrication tasks. Designed for heavy-duty applications, these tables offer smooth height adjustments, ensuring optimal positioning for precision work. With a sturdy construction and customizable load capacities, they are ideal for workshops requiring flexible and reliable lifting solutions

Want to try one in your workshop?

We build every table in-house at Cyclotron, fully compatible with our D16 and D28 modular accessories. Pneumatic actuation, rock-solid build quality, and real-world toughness — this table was made for serious welders who don’t mess around.

Just drop us a message or call, and we’ll walk you through the options.

How to choose a suitable welding table?

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

Benefits of Rotary welding table

The use of rotary welding tables in the manufacturing industry has drastically increased due to the increase in production rate, better welding quality, greater Business ROI, and many more.

Types of Welding tables

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.