FAQs for Welding tables (Part 1)

Find answers to all your welding table questions, including size, surface finish, load capacity, & more.

Let Cyclotron help you buy the right one.

FAQs for Welding tables (Part 1)

Table of Contents

Faqs for welding tables (Part 1)

1. What Size of Welding Table Do I Need?

The size of the welding table depends on the jobs you handle and the space you have. For smaller workparts or light welding tasks, a compact or mid-sized table is enough. If you are working with heavy, complex, or irregular components, choose a larger table.

Suppose the size of your part is 800*1200mm then the size of your welding table should be +200-300mm than the size of your part. In this case the size of your welding table will be around 1000*2000mm which is a standard size.

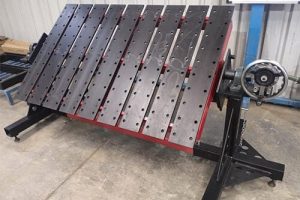

Going with 3D Table will help in increasing the working area for fabrication and clamping system by making use of the side plates mounted on the table, this extension of working are is not possible in 2D welding table.

Common welding table sizes are 1000 mm × 1000 mm, 1000x2000mm, 1200 mm × 2400 mm, and 1500 mm × 3000 mm, depending on the welding requirements.

2. What is the materials used in welding tables?

- The material of your welding table plays a big role in performance and weld quality.

- Mild steel is a popular choice for welding. It is strong, easy to maintain, and conducts electricity well, which is useful for grounding. With a thick tabletop, mild steel tables can easily handle high heat and heavy impact without trouble.

- For precision welding tasks, cast iron is reliable choice. It stays flat and stable, enhancing welding accuracy. However, it’s brittle and not ideal for jobs that involve grinding, hammering, or repeated impact.

Aluminum is reputable for its light weight and resistance to corrosion. This makes it suitable for portable or temporary setups. But due to its low melting point and tendency to deform under heat or force, it isn’t a good option for active welding.

Choosing the right welding table material matters. A good welding table should resist corrosion, stay flat under high temperatures, and withstand impact without warping. If any of these are compromised, so is your weld quality.

3. What's the weight capacity of welding tables?

- To choose the right table, start by considering the weight of your heaviest jobs. The table must support the workpiece, any clamps or fixtures, and its own structure without bending or shifting. It also needs to handle heat and occasional impact during welding.

Welding tables come in three categories based on load capacity: - Light-duty tables are perfect for small workshops and lighter projects having a weight capacity of 200 to 400 kgs. Cyclotron’s Ecoflex series with 12 mm thickness can give you weight capacity of around 200-400 kgs

- Medium-duty tables are suited for more frequent use and moderate loads with capacity around 500-1500 kgs. Cyclotron’s D16 Series with 16 mm thickness can give you weight capacity of around 500-1500 kgs

- Heavy-duty tables are built for industrial applications and can handle anywhere from 1 ton to 8 tons, depending on the model and the size. Cyclotron’s D28 Series with 25 mm thickness can give you a weight capacity of around 1000-8000 kgs.

How to choose the right brand for welding table?

- Define Your Requirements Clearly - List your welding applications, part sizes, workspace limitations, and budget. Identify the features you need: modular design, flatness tolerance, clamping holes, etc.

- Compare Brands and Specifications - Don’t go with the lowest quote. Compare build quality, brand value, surface finish, thickness, accessories, and clamping systems. Also review warranty coverage and customer support. This is a long term investment for you, going with the lowest quote won’t always guarantee the best product for you.

- Think Long-Term - A cheaper table may cost you more in the long run. Poor flatness or instability can lead to defective welds, lower quality, and wasted material. A well-built welding table pays for itself over time..

4. How flat is the welding table surface?

Flatness and stability are critical for accurate, high-quality welds. Even slight unevenness can lead to misalignment, distortion, or gaps, especially in complex or multi-part assemblies.

While standard laser-cut welding tables typically offer 0.8-1mm/M flatness across the surface, this is sufficient for light to medium fabrication work.

At Cyclotron, our professional-grade welding tables have a flatness tolerance of 0.1 mm per 1000 mm, providing high-precision for demanding jobs.

For added stability, welding tables come with adjustable leveling feet options allowing you to compensate for uneven workshop floors. This improves weld accuracy and also enhances operator safety during use.

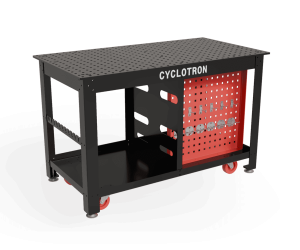

5. Should I Choose a Table with Fixed Legs or Casters?

The decision depends on your workspace and the kind of jobs you handle.

If you are working with heavy parts or complex components, fixed legs are the better choice. They offer maximum stability and support higher loads

Casters increase mobility, which makes it easy to move the welding table around. However, they can reduce stability and load capacity. That said, with the right type and proper installation, this impact can be minimized.

At Cyclotron, our modular welding tables can be customized with heavy-duty casters, giving you the flexibility to move them without sacrificing performance.

6. What Clamping and Fixturing Options Are Available?

Clamps and fixtures help hold your workpiece firmly in place while welding. Modular welding tables come with evenly spaced holes on the surface, which makes it easy to use different types of clamps and tools.

You can add L-brackets, T-slots and locking clamps depending on your job. These allow you to adjust and fix parts quickly at any angle or position.

The biggest benefit of a modular table is flexibility. You can set it up for different work types without losing precision.

Cyclotron welding tables are designed to support all standard fixturing and clamping systems, so you can work faster and more accurately with less hassle.

How to choose a suitable welding table?

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

Benefits of Rotary welding table

The use of rotary welding tables in the manufacturing industry has drastically increased due to the increase in production rate, better welding quality, greater Business ROI, and many more.

Types of Welding tables

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.