Grinding table

Grinding table

In the manufacturing and metal fabrication sectors, controlling the debris and dust particles is essential. This promotes a clean working environment and also ensures the highest safety for the operators.

The grinding operation generates fine particles that may turn into airborne particles. It is important to extract these particles and the debris during the operation. Failing to remove them poses a severe threat to the health of the operator, the workplace, and also the grinded workparts. Today, we will explore the importance of grinding tables, downdraft grinding table, and their benefits and applications

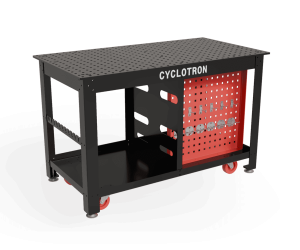

What are Grinding Tables?

-

Grinding tables are the specialized tools specifically used in grinding, welding, polishing, and sanding operations. They provide a strong base to hold the surface while drawing the debris and dust particles generated due to the operation.

These grinding tables often integrate with the dust collection systems and are further connected to the external ventilation system.

Without the grinding tables, the operators are exposed to fine grinding particles, airborne particles, sparks, grinding debris, and more, leaving them vulnerable to serious health hazards and affecting the safety of the workspace.

Benefits of Grinding Tables:

They are more than just solid surfaces for grinding operations. Here are some of the functions of grinding tables:

- Extraction of Fumes & Dust Particles

During the welding operation or grinding of metal, wood, or composite materials, toxic fumes, and fine particles are released into the atmosphere. Breathing such particles by the operator can cause severe respiratory problems for the operators. Grinding tables have a strong suction system that collects dust particles and keeps the working space clean. - Improve the Cleanliness of the Workspace

As the grinding tables are designed to drain out the debris continuously, the working area remains clean, providing a clearer view during the grinding operations. It improves the grinding quality and minimizes the post-grinding cleanup tasks. - Enhance Worker Safety

The grinding tables are designed with flexibility and ergonomics in mind. This enables the workers to move freely and adjust the equipment according to their comfort.

As a result, the operator fatigue is greatly reduced, resulting in increased efficiency and higher grinding productivity.

Improve Grinding Productivity

When the grinding debris, dust particles, and sparks are effectively handled, you will provide a safe space and clean environment for the worker to focus on teh operation. As a result, the grinding productivity and quality are greatly enhanced.Reduce Fire Hazard

Grinding, particularly metals, can generate flying sparks. If not protected, these sparks fall on the operator and in the vicinity of the working space, likely causing injuries to the operator and other operators working near that area. The grinding tables come with built-in spark arrestors and fire-resistant materials that can prevent sparks from igniting from dust in the air, thus minimizing the risk of fire hazards in the workplace.

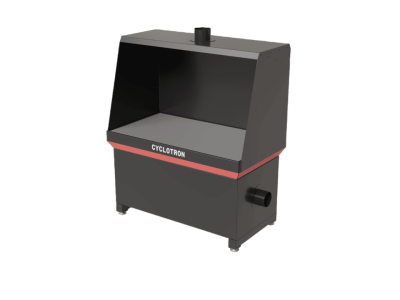

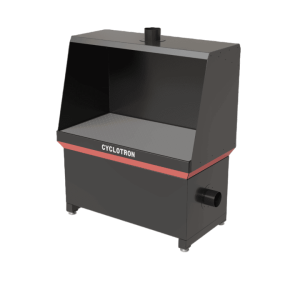

Downdraft Grinding Tables

A downdraft grinding table performs the functions of an air filtration system. Basically, they come with a flat table surface with perforated holes. But below the holes is a powerful suction system that draws the airborne particles, debris, and dust through the holes, keeping the working space clean and safe for the operator. The downdraft grinding tables usually come with:

- Built-in fans or attached to the centralized dust collectors

- Sturdy construction to withstand the grinding operations

- Customizable airflow controls and fire-resistant surfaces to prevent fire hazards from sparks generated during the operations.

The downdraft tables come in different models depending on the purpose, like woodworking, metals, composite, etc. A metal downdraft table is specifically designed for grinding and finishing metal operations. Let’s explore metal downdraft grinding tables:

Metal Downdraft grinding tables

Grinding metals like steel, aluminum, and titanium releases intense heat, sparks, and heavier dust particles. A regular downdraft grinding table cannot suffice as it needs a robust build with specialized features to handle the intense heat and sparks.

Features of a Metal Downdraft Grinding Table:

- Spark Arrestor

Metal grinding produces high-energy sparks that can ignite the dust filters. Metal downdraft grinding tables come with a spark arrestor system to capture the sparks at the source and cool them before they reach teh dust filters. - High-level CFM system

CFM is the amount of airflow suction by the machine in cubic feet per minute. The metal downdraft tables have high-CFM suction systems to effectively capture heavier air-borne particles, dust, and debris.

Integrated Filtration Systems

The machines come equipped with high-efficiency particulate air (HEPA) filters or cartridge filters that can capture fine metallic particles released from grinding metals.Abrasion Resistance

The surface of the table and its internal components must be resistant to abrasion, wear, and tear from the metal fragments.

Conclusion

Grinding tables are invaluable tools in metal fabrication and manufacturing operations. The extraction of debris and fumes improves operator safety, adheres to health and safety standards, and enhances the cleanliness of the workplace. Among the grinding tables, the downdraft and metal downdraft grinding tables offer next-level protection by capturing dust particles right at the source. If you are working with metals, investing in a high-quality metal downdraft grinding table is essential to prepare you for long-term success. If you are looking for a good grinding table or downdraft table wih customizable features, look no further than Cyclotron Automation. We provide superior quality grinding tables, with advanced filtration systems and remote controls, so that your workplace stays clean and healthy. Schedule a call with us today.

Our Products

How to choose a suitable welding table?

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

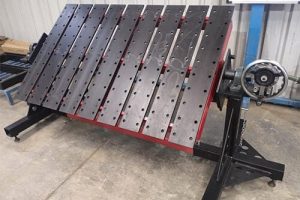

Benefits of Rotary welding table

The use of rotary welding tables in the manufacturing industry has drastically increased due to the increase in production rate, better welding quality, greater Business ROI, and many more.

Types of Welding tables

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.