How to choose a suitable welding table?

How to choose a suitable welding table?

Did you know that a high-quality welding table can improve your welding quality and provide comfort whether you are a welder or has anything to do with fabrication. They can significantly impact your project results whether you are experienced or beginner. There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness? This article is going to cover all the above questions, so you don’t have to worry.

What is a Welding table?

- A flat & stable surface for welders that safely support welding pieces. Fixture tables take care of your comfort by allowing you to stand or sit while welding. They also take care of incredibly high temperatures and support high power machinery. .

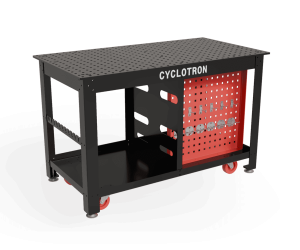

- CYCLOTRON welding tables are built with taking all the welding Ergonomics into consideration. They have adjustable moving wheels for portability on the shop floor. They are electrically conductive, which allows you to connect a ground to the table instead of the metal pieces that you’re welding. With all these pros one can definitely say that welding tables are worth investing in

When choosing a welding table, things you should consider are:

Size of the welding table: Fixture tables comes in various sizes and shapes. Starting from 1 x 1m and goes up to more than 5m in length. These table with modular sizes in order to adjust the table sizes for different work projects.

If your welding projects have big and heavy metals involved it is better to go for larger tables. If your projects are smaller in dimensions but heavier (greater than 2 tons) in weight, it is better to go with 25mm thickness tables rather than smaller 16mm thick.

People having projects which are less than 200 kg in weights can opt for 12 mm thick table.

Depending upon the size of the fixture it is advisable that the complete fixture should be placed on the table

Hole pitch:

The standard hole center distance of welding tables is 50mm. When your welding projects are larger in size it is better to go with a 100 mm distance in order to reduce the table cost.

Legs

In standard configuration, legs come with two options

- With leveling pads

- With Castor wheels

If you have a small welding shop and YOU don’t have to move the table every now & then, go with the leveling pad option. But if you have a big shop floor or heavy work pieces & need to move from one place to another, Castor wheels are the best.

Type of welding table

- 3D Welding Tables: - Here YOU get 5 precision machined surfaces. These types of tables provide you with clamping options outside the table with help of side plates.

- 2D Welding Tables - The top surface is precision machined. Smaller workpieces can go with these types of tables.

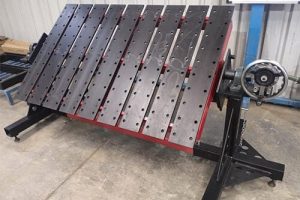

- Rotary Welding Tables - Has rotating top surface. This type of table is used for welding projects where the welder can sit at one place, and the welding position can be brought to the welder for increased accuracy in welding.

Buy branded table:

Buying a branded table will always give you benefits in terms of accuracy of the table, finished materials, modularity, the welding clamps options, service they provide.

Thus, investing in a welding table would be great for your Business ROI. A welding table can increase your welding quality and provide you with a safe and stable surface. With the above information, it will be easy for YOU to pick up your best suitable welding table for your next project.

Well, CYCLOTRON provides you the best welding tables perfectly suitable for each of YOUR welding projects. Check out our products.

How to choose a suitable welding table?

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

Benefits of Rotary welding table

The use of rotary welding tables in the manufacturing industry has drastically increased due to the increase in production rate, better welding quality, greater Business ROI, and many more.

Types of Welding tables

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.