Blogs By Cyclotron

Welding Clamps

Welding clamps are used to hold components or work parts temporarily together while performing operations like welding, woodworking, carpentry etc.

What are welding clamps?

Do you want to create a precise welding joint with minimal effort? The secret lies in securing your workpiece in a stable position so that welders of any skill level can perform welding precisely. This is where welding clamps come into play. When fixed on the welding table, these welding clamps firmly hold the workpieces to be welded and ensure an efficient and precise welding operation for the welders.

Welding becomes particularly challenging when dealing with inclined workpieces. But, welding clamps address this by providing a secure hold at the desired inclination. This, in turn, helps operators to focus on welding without the need to constantly adjust the components.

The welding clamps are available in various types and sizes, each serving specific purposes. Each type of clamp plays a unique role in enhancing the efficiency and precision of welding operations, catering to the varied needs of welders working with different materials and dimensions. Here are some of the commonly used welding table clamps:

Does fixture and clamps both mean the same?

Clamping elements are an integral part of fixturing that hold parts together temporarily without damaging them. In an operation like welding, clamps are must-have tools for improved quality and accuracy of the product.

Though there are many weld clamps available, the type of welding clamps depends mainly on two aspects:

What is the role of clamps for your project?

What is the precision of the job you get using the clamps?

Types of weld clamps

There are clamps of different sizes and shapes each serving a specific purpose. Here are the most commonly used weld clamps:

C Clamp:

The Carriage Clamp or C Clamp is the most widely used welding clamp to hold the parts together using some pressure. The clamp holds the part by turning the screw towards the part. However, it takes the instant and quick release of the part is not possible as it takes some time to loosen the screw and remove the work part. The C clamp is also called a G clamp.

Locking clamps

A locking clamp offers firm clamping force on the work parts and holds them together in correct alignment. The shape features a c shaped jaw that incorporates a lever mechanism to hold workpieces. They are mainly used in welding smaller components and can be operated with a single hand.

Spring clamp

Spring clamps come with a spring mechanism to secure two workpieces together during welding. These fixture clamps are designed to provide a strong grip through a spring-loaded mechanism, allowing for quick gripping and adjustments. They come in various sizes, with small clamps suited for delicate work and larger ones for heavier tasks. Their easy-to-design makes them desirable in welding conditions where the area is limited. The clamps’ jaws are closed by squeezing the ends, and when the handles are released, the clamps return to their original position, releasing the jaws and, consequently, the workpieces.

Two-Axis Clamp

The two-Axis welding angle clamp lets you hold work parts at an angle accurately. The work part with non-uniform thickness can be held by this clamp easily. You can quickly align the workpiece to be welded at an angle of 90 degrees accurately. Also, the provision of a rotating spindle or floating head lets you hold workpieces of different thicknesses.

Ball lock bolts

The Ball lock bolt or Quick grip clamp is a fast and highly versatile clamping tool when you have to clamp objects in the minimum time. It can be released or tightened with a single hand and is hence known as a one-handed clamp. The mechanism is designed in such a way that you can open or close the jaws of the clamp in a single movement. This type of clamp is highly useful when you have to grip large or heavy objects and hold the workpieces in the other hand. For large works, multiple clamps are required to hold workpieces effectively till the welding is performed.

Looking for welding tables and clamps.Do fill the form and our team will contact you shortly

Pipe Clamp

The pipe clamp operates similar to an F Clamp except that it uses a pipe instead of a sliding bar as in an F clamp to hold work parts in proper alignment. They are quick, easy and safe to operate which are used for centering and alignment of the steel pipes before pipe welding.

When it comes to securing pipes during welding, the go-to solution is the use of pipe welding table clamps. These clamps are designed to flawlessly secure pipes of varying diameters. Known for their sturdiness, they offer enhanced stability and control over the workpiece, ensuring precision in welding operations.

Magnetic Clamps

Magnetic clamps are another extra set of helping hands to assist you in holding metallic work parts together at required alignment. The only difference between conventional clamps and magnetic clamps is that the former uses screws, bars etc to hold the part but the latter serves the purpose with the help of magnetic force. They are efficient, easy to use and enhance the productivity of the welding. However, one disadvantage of using a magnetic clamp is that if you are not cautious about the type of materials you hold using the magnetic clamps, the magnetic field can get into the material while welding and affects the material severely.

Pic source: Google

Looking for welding clamps?

We at Cyclotron Automations design and manufacture all types of Welding clamps. Take a look at the types of welding clamps here.

Cyclotron Welding clamps

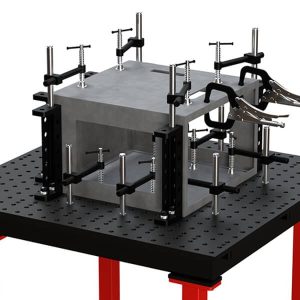

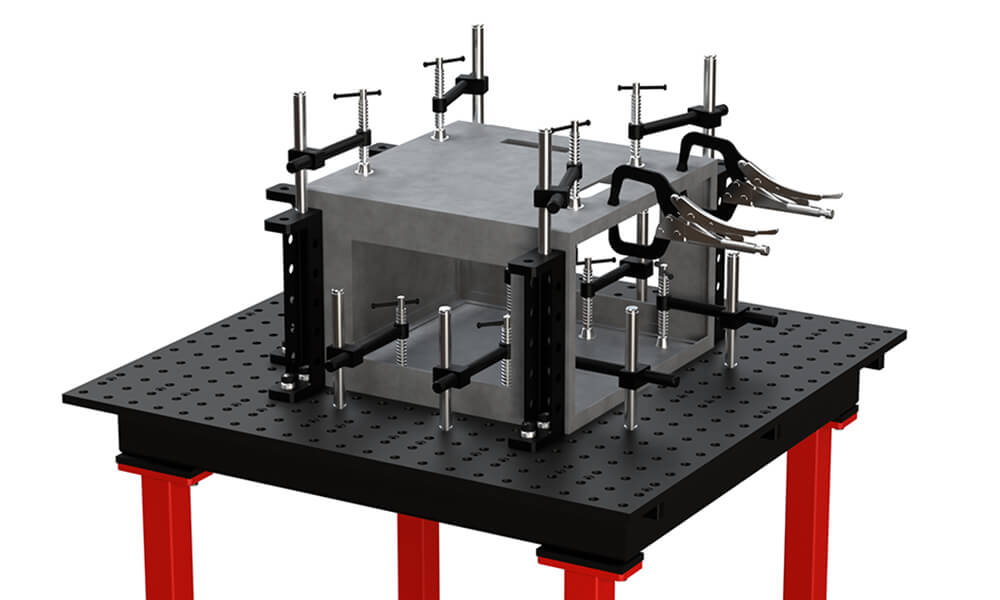

Modular welding tables & welding clamps

Metal Box Fixture on welding table

Bed Frame Fixture on welding table

Stair Rail Fixture on welding table

Control Panel Fixture on welding table

Blogs by Cyclotron

Published on-2/03/2024

Types of welding clamps and their uses in particular way

Blogs by Cyclotron

Published on-17/08/2021

Get to know about Modular welding fixtures and their Importance

Blogs by Cyclotron

Published on-23/07/2021

Get to know about types of welding tables and their applications

Our valuable customers