Blogs BY CYCLOTRON

Welding table prices in India starts

from 50,000 and can go upto

5,00,000 + depending on the size,

material of construction,

precision, etc.

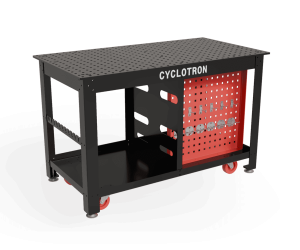

Cyclotron, Jagdeep, Weldex, weldor, makweld are the top welding table brands in India Cyclotron welding table is the most precise welding table manufacturer

FAQs for welding tables

Find answers to all your welding table questions, including size, surface finish, load capacity, & more.

Let Cyclotron help you buy the right one.

How to choose a suitable welding table?

There are plenty of things while considering a suitable fixture table for YOU. It could start from what should be the size? Should it be 3D, 2D, Rotary, or slotted table? What should be the thickness?

Cast Iron vs Mild Steel Welding Table

Mild steel and cast iron are two common materials used for welding tables. To assist you in selecting the one that best suits your needs, this article deconstructs their salient characteristics.

Types of Welding tables

Most of the welders perform all the fabrication work on the floor. One can work on the shop floor without a welding table. No grounding needed, no worry about cutting the base etc.

Cyclotron Welding Clamps

Welding clamps are used to hold components or work parts temporarily together while performing operations like welding, woodworking, etc.

Benefits of height adjustable welding tables

Benefits of Cyclotron’s height adjustable welding tables

Cyclotron Modular Welding fixtures

A Modular Welding table comes with several holes to accommodate fixturing and attaching other components effortlessly. It is designed to suit the changing technologies. This modular facility makes fixture components

Welding Hazards

Welding Hazards | According to the bureau of labor statistics, more than half a million welders in the world either die or get injured every year.

Top 10 causes of welding spatter & ways to reduce

1. Metal composition

2. Presence of impurities

3. Poor handling of Welding equipment

4. Welding parameters

5. Wire feed problems and so on

Top 8 Welding safety Tips

Providing a safe environment to the workforce is as important as getting the work done. In the previous article, we have been through various hazards caused in welding operations ranging from mild to severe health injuries that can be fatal.

Welding Hazards

Welding Hazards | According to the bureau of labor statistics, more than half a million welders in the world either die or get injured every year.

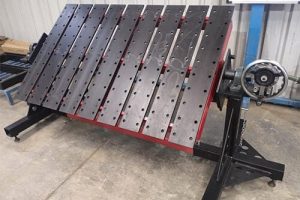

Benefits of Rotary welding table

The use of rotary welding tables in the manufacturing industry has drastically increased due to the increase in production rate, better welding quality, greater Business ROI, and many more.

Materials Used in Welding tables

Materials used in welding tables are Carbon steel, Stainless steel, Aluminium, Cast iron, etc.